Episode 5: GMPs in a Dietary Supplement Program

Episode 5: GMPs in a Dietary Supplement Program

In this episode, we are going to focus on the prerequisite programs and good manufacturing practices, or GMPs, that support the systems we’ve already discussed to operate a properly run dietary supplement facility.

Because supplements are regulated in a framework that is similar to food facilities, many GMP expectations are like-to-like with food factories, and throughout this episode we will mention where these similarities exist.

As we dive into the details, we should first point out that GMPs stand for Good Manufacturing Practices. GMPs are applicable to all manufacturing operations: food, supplements, pharmaceuticals, and other non-food operations.

Hygiene Programs

While your facility may have one set of processes to make one kind of product, or several different processes to produce multiple product types, your GMP’s will remain generally constant to support all of your production operations.

One of the main areas we see this is in our hygiene program. Your hygiene program may include the clothing and protective equipment employees wear, the methods of changing into that attire, as well as general cleanliness practices during operations.

Hygiene programs can also include managing of tools, personal items and medicines, food and drink as well as how first aid is applied where it is needed.

Dietary supplements are almost exclusively ready-to-eat, and practices for supplement operations are the same as high risk ready-to-eat food operations.

Maintenance and Sanitation

As we move from hygiene requirements to those requirements for sanitation, maintenance, and warehousing, it is important for us to note that food operations and dietary supplement operations are very similar in the practices around these prerequisite or GMP programs.

Because supplements are high risk, and operations are performed in clean rooms, there is a higher degree of care required. However, maintenance operations in both food supplement operations are very similar.

The same holds true for cleaning and sanitation in a supplement operation.

One significant difference to note, unlike low risk food operations, it is expected that all dietary supplement operations have robust and extensive verification activities as part of the cleaning and sanitation operations.

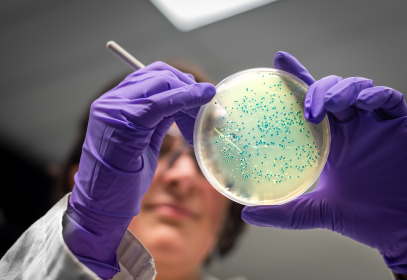

ATP swabbing must be performed after each cleaning event and a robust environmental monitoring program must be in place.

Water Quality, Air Quality, and Utilities

Another GMP or prerequisite program that differentiates supplement operations from food operations is the monitoring and control of air flow in the facility, as well as the careful monitoring of water, utilities, and general warehouse upkeep.

Again, dietary supplements are mostly ready-to-eat products, and as such, the GMP or pre-requisite program requirements are treated as high-risk.

As such, one of the primary GMPs that distinguishes dietary supplements processing from food processing is the controls of air flow and air pressure. For dietary supplement clean rooms, air pressure is at a minimum, expected to be assessed, and at the gold standard, a control system and careful monitoring of air pressure would be in place.

Summary of GMPs in a Dietary Supplement Program

With careful monitoring and proper control over hygiene, maintenance, and sanitation your facility should be ready to produce safe, high quality supplements made to industry standards.

When these GMP or prerequisite programs are properly controlled and implemented alongside operational programs such as the MMR, inventory and label controls, and product testing, a dietary supplement operation is ready to pass regulatory inspections.

Free Manufacturing Master Record Checklist Download

If you would like to discuss having Kellerman Consulting write and implement your food safety and quality management system program, contact us for a free consultation.

Free Dietary Supplement Manufacturing MMR Checklist