Food Safety Training Videos and Free Downloads

Choose A Topic To Learn More & Download Free Resources

Kellerman Consulting offers an extensive library of food safety & quality management system videos and free downloads, which are designed to make it easier for Food Safety & Quality Assurance professionals to meet the food safety certification, quality management system certification, and FDA/USDA compliance requirements for their facility. Watch our free training videos, download our free food safety & quality management system tools, or become a client and access a package of employee food safety training videos, quizzes, and training logs that are not publicly available – at no additional cost in both English and Spanish.

Episode 3: Critical Quality Metrics & KPIs

In this episode we focus on the specific verification concepts within operations that are used in complex quality management systems, namely critical quality metrics and key performance indicators used to monitor processes and verify the effectiveness of the quality management system.

Episode 4: Training of QA & QC, Critical Quality Metrics, & Key Performance Indicators

In this episode, we are going to discuss training requirements for quality control personnel and compare them with the training requirements for quality assurance personnel involved with the quality management system. We are also going to touch on specific ISO training recommendations for organizations pursuing or maintaining ISO certification.

Episode 5: Internal Auditing, Top Management Review of the QMS, Critical Quality Metrics, & KPIs

In this episode we discuss the primary review functions of a quality management system, which is the internal audit and the management review of the quality management system, critical quality metrics performed as part of quality control checks, and the key performance indicators that are part of the quality assurance function of operations.

Episode 6: ISO Quality Management Systems

In this episode we are going to focus on ISO certification as it connects to QA and QC actions. We will continue to use the framework of critical quality metrics and their direct connection to quality control, as well as key performance indicators linked to quality assurance within the quality management system, and through that lens we can understand the basic framework of ISO.

Episode 4: Testing in a Dietary Supplement Program

In this video we cover the requirements for testing in dietary supplement programs and how to ensure that your program is designed to meet regulatory requirements of 21 CFR 111 and GMP requirements from 21 CFR 117 as they apply to dietary supplements.

Episode 1: Introducing Validation and Verification

The concepts of validation vs. verification are commonly confused. During the course of this video series we will clarify these topics using examples from our experience in food safety & quality assurance and we will explain the differences between validation and verification.

Episode 3: Long Term Planning of Validation and Verification

In this episode of our Validation and Verification series, we focus on the long term aspects of validation within organizations and the best ways to approach and plan for improving these larger aspects of an organization when invalid conditions are found or where improvement is sought.

Episode 5: Validation and Verification of Critical Safety and Quality Equipment

In this episode we are going to focus on the validation requirements for critical safety and quality equipment, the sources of scientific information required to prove validation, and the verification actions within a safety and quality plan to assure successful regulatory and audit review of those requirements.

Episode 6: Regulatory Requirements and Challenge Studies

In this episode we are going to continue our look at validation and verification of critical equipment, and we are going to focus on regulatory requirements for food facilities for validation and verification as part of HACCP or Process Controls.

Episode 7: Validation and Verification of Metal Detectors and X-rays

In this episode you will learn how to properly validate foreign material control equipment, including a metal detector and an x-ray. In order to understand how to properly validate a metal detector or x-ray, we need to first explain the challenges.

Episode 5: Document Control

Record keeping and document control are necessary activities in any food production operation. It is important to ensure all documented information is easily accessible to individuals who may need access to that information, and that all changes made to your program are well documented and the revisions are controlled.

Episode 4: Handwashing & Hygiene

In this training, we will cover topics including: personal hygiene for staff involved in the handling of food products, hazards associated with personal hygiene, why hand washing is so important in food safety, when hands should be washed, and how to properly wash hands.

Episode 3: Food Defense Plan

In this episode, we will consider potential security risks in your facility and the actions you can take to protect our food system. The FDA FSMA final rule issued in December 2013 requires facilities to assess their risk, implement mitigation strategies, and ensure those strategies are working as intended.

Episode 3: Food Defense Plan

In this episode, we will consider potential security risks in your facility and the actions you can take to protect our food system. The FDA FSMA final rule issued in December 2013 requires facilities to assess their risk, implement mitigation strategies, and ensure those strategies are working as intended.

Episode 4: Handwashing & Hygiene

In this training, we will cover topics including: personal hygiene for staff involved in the handling of food products, hazards associated with personal hygiene, why hand washing is so important in food safety, when hands should be washed, and how to properly wash hands.

Episode 5: Document Control

Record keeping and document control are necessary activities in any food production operation. It is important to ensure all documented information is easily accessible to individuals who may need access to that information, and that all changes made to your program are well documented and the revisions are controlled.

Episode 1: What An Internal Audit Is and Why You Should Perform Them

As an introduction to this video series, we examine what an internal audit is, what organizations should perform internal audits, how to properly and effectively perform an internal audit, and how to use the results of those internal audits to evaluate and improve the safety or quality management system.

Episode 2: Setting up an Internal Audit

In the second episode of the internal audit video series, we review the most important aspects of internal auditing, all of which occur prior to performing the internal audit. Planning and preparation must occur prior to any internal audit in order to have a successful outcome.

Episode 3: Performing the Audit

During this episode we discuss how to perform the internal audit and best approaches during the audit to help achieve a successful outcome. A successful outcome of an internal audit does not mean that the organization passes the audit, but rather that the audit accurately reflects the state of the organization at the time of the audit.

Episode 4: Corrective and Preventive Actions for Audits

During this episode we discuss how to properly address non-conformances or opportunities for improvements discovered over the course of an internal audit. Corrective actions and preventive actions as a result of internal audits are a special circumstance and require a special review.

Episode 5: Software Solutions for Internal Audits

When we look at the role software plays in auditing in the fifth episode of Kellerman Consulting’s internal audit video series, we are going to be focusing on the audit method, since this is where software provides the biggest benefit, as well as the biggest challenges.

Episode 6: Internal Auditing in Quality and Safety Certification Programs

In the final episode of this video series, we focus on the Quality Management System and GFSI requirements for internal auditing. ISO and GFSI programs operate on many similar programs and these schemes have a requirement to internal audit the program as part of yearly activities.

Episode 1: Accountability & Core Values

We will set a framework in this video to help you create a culture of food safety in your operation. You will hear about how accountability is an essential part of building a culture of food safety by leadership and employees taking responsibility for actions and interactions in the facility.

Episode 2: Structure and Delegation

This video describes how to properly set up organizational structure, and emphasizes the importance of delegating tasks to assure a culture of food safety. The structure must be written down in the form of an organizational chart in order to have a culture of food safety. We offer strategies for effectively delegating tasks in this video.

Episode 3: Key Metrics

The third video in our series expands on the culture of food safety with the introduction of key metrics or key performance indicators (KPIs) within the facility and program. A key metric or performance indicator is something we measure within operations to determine if our process works, and if the organization is functioning.

Episode 6: Culture of Food Safety in GFSI

The final in our series examines the different ways each Global Food Safety Initiative (GFSI) certification program incorporates a Culture of Food Safety. This video will give you an idea of what these certification programs are looking for in regards to a Culture of Food Safety.

Episode 3: Traceability During Receiving and Stock Rotation Practices

In the third episode of the Traceability in Food Businesses video series, we discuss what type of traceability information to document at the point of receipt for incoming materials, as well as the basics of proper stock rotation practices.

Episode 4: Traceability During Work-in-Process and Rework

In the fourth episode of the Traceability in Food Businesses video series, we focus on traceability during processing and discuss the importance of using batch records. We also review the identification of both WIP and rework materials and how documenting the use of these materials is critical to a site’s traceability system.

Episode 5: Tests of the Traceability System and Recall Program

In the fifth episode of the Traceability in Food Businesses video series, we discuss how and when to conduct a traceability exercise, as well as what to document as part of the exercise. We also review how trace exercises and mock recalls are different from one another, and the importance of testing both.

Episode 6: Traceability in GFSI

In the final episode of the series, we discuss the traceability and mock recall requirements for each of the major GFSI schemes: SQF, BRCGS, FSSC 22000, and PrimusGFS. Even if your facility does not operate under a GFSI scheme, this video includes helpful information for those considering implementing a best-in-class traceability program.

Episode 1: Allergen Risk in Food Facilities

In Kellerman Consulting’s allergen series we focus on some of the difficult issues many facilities face when employing allergen controls in food and food packaging facilities. We cover some basic background information about allergens, and standard criteria used to determine how large of an allergen program is appropriate for a facility.

Episode 2: How Allergens are Controlled in Food Facilities

This video offers important information for controlling In the second episode of Kellerman Consulting’s video series, we review the different controls that can be applied to allergens in the facility and how those controls can work together to assure all of the risks associated with allergen contamination and mislabeling are reduced or removed.in your facility. Allergens are the number one reason for food safety recalls in the United States. Allergic reactions from unlabeled foods can cause severe illness, hospitalization, and even death.

Episode 3: Monitoring Allergens in Operation

In Kellerman Consulting’s third episode of the Allergen series, we look at the main ways that allergen verification is achieved for a valid allergen control program. The first verification activity is the allergen assessment in the facility. This is a practice that should be done by all facilities, regardless of whether they determine themselves to be low risk, medium risk or high risk.

Episode 5: Allergen Programs in GFSI

Allergen controls are mandatory requirements for each GFSI scheme. All facilities must have assessed the risks allergens pose, identified controls for those risks and conducted training to all production staff on the basics of allergens and the risks they cause to those who are allergic.

Episode 7: Supplier Approval in GFSI

In this episode we discuss the supplier approval requirements in the major GFSI schemes including: SQF, BRCGS, FSSC 22000, and PrimusGFS. Since all food safety programs must have basic controls over the safety of food or food packaging produced, each of the major GFSI schemes require the highest standards for supplier approval programs.

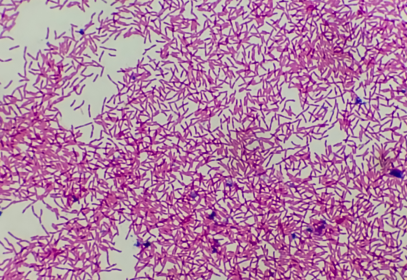

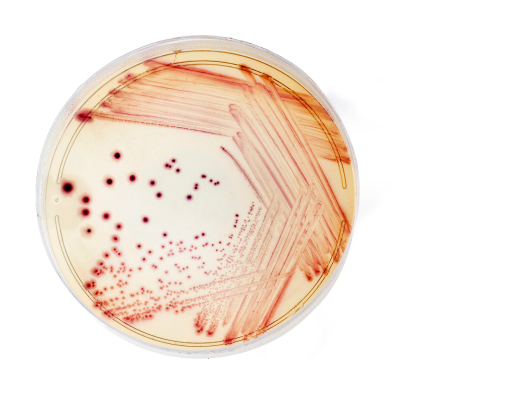

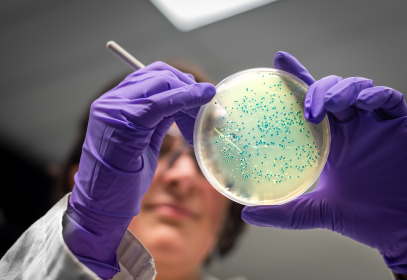

Episode 1: An Introduction to Environmental Monitoring Programs

Let’s begin with the basics of implementing and operating an environmental monitoring program for food and food packaging facilities. To do so, we start with what an environmental monitoring program is for, and what the first steps are in setting the program up.

Episode 4: Swabbing Drains in Environmental Monitoring

For facilities with established environmental monitoring programs, drains present a unique challenge and opportunity to monitor for organisms, and thinking through the approach to including or excluding drains from the swabbing schedule is important.

Episode 5: Complex Swabbing Patterns

We continue our look at advanced practices in environmental monitoring in the 5th episode of this video series. We need to look at strategies and patterns for swabbing to assure that we are successful in tracking down pathogens, and to eradicate them before they get near areas where equipment or product is at risk.

Episode 6: Environmental Swabbing in Meat and Poultry Facilities (FSIS)

In this video series we have focused on how to build an effective environmental monitoring program for food and food packaging facilities. Regulatory oversight in these programs often occur during infrequent visits that are conducted annually, or even less frequently. One major exception are facilities under FSIS jurisdiction, in which regular oversight occurs, often every day.

Episode 9: Environmental Monitoring in GFSI Programs

Each of the major GFSI programs, SQF, BRC, FSSC 22000 and PrimusGFS programs all require fully implemented environmental monitoring programs to be in place as part of the safety and quality programs, including risk assessments justifying the approach taken in the facility.

Episode 3: Ongoing Preventive Maintenance

In this episode we look closely at preventive maintenance to prevent equipment breakdown. Preventive maintenance is important to avoid expensive and possibly critical breakdowns of equipment in operations, and it is also an important part of demonstrating control in a functioning quality and safety management system.

Episode 1: Problematic Events in the Facility

Problematic events in a food facility can be categorized by process deviations and facility problems. Process deviations are instances of undesirable results that deviate from your normal operating procedures or product specifications. Facility problems, on the other hand, can be described as problematic events caused by failures of the facility, equipment, or even employees working in the establishment.

Episode 2: Root Cause Analysis, Corrective Actions and Preventive Actions

In Kellerman Consulting’s second episode of the CAPA video series, we discuss the differences between corrections, corrective actions, and preventive actions. We also focus on the importance of conducting a root cause analysis as part of your CAPA program in order to implement sustainable procedural changes and ensure long term success of the actions taken.

Episode 3: Documenting Non-Conformances, Root Cause Analyses, Corrections, Corrective Actions, and Preventive Actions

In Kellerman Consulting’s third episode of the CAPA video series, we talk about how to properly document a root cause analysis investigation, corrections, corrective actions, and preventive actions. Additionally, we review why proper documentation of a CAPA program, and the communication of these events are so critical to an organization’s food safety culture.

Episode 4: Deviations Involving Key Metrics

In the fourth installment of Kellerman Consulting’s Corrective and Preventive Action video series, we discuss deviations involving key metrics. In our Culture of Food Safety video series, we cover key metrics, or key performance indicators (KPIs), and how the routine monitoring of these metrics provides an organization’s leadership with a means of measuring the performance of the business.

Episode 5: Impunity and Disciplinary Actions in CAPA Programs

In the fifth installment of the Corrective and Preventive Action video series, we discuss impunity and disciplinary actions as part of a facility’s CAPA program. Deviations or nonconformances caused by an employee error or failure to follow an established procedure is a common occurrence in a food facility; however, because of their nature, these types of nonconformances must be handled differently than process or equipment related deviations.

Episode 6: Management and Auditing of the CAPA Program

In the sixth installment of the Kellerman Consulting Corrective and Preventive Action video series, we discuss management and auditing of the CAPA program. Internal audits and management reviews of programs and policies are a nonnegotiable part of a culture of food safety, but it is particularly important for the success of the CAPA program.

Episode 7: CAPA Programs in GFSI

In the final episode of the Kellerman Consulting CAPA video series, we discuss the key components of a CAPA program for each of the major GFSI schemes: SQF, BRCGS, FSSC 22000, and PrimusGFS. Even if you do not operate under a GFSI program at your facility, this video provides important information for those considering implementing a high-level CAPA program into their organization.

Preventive Maintenance & Repair Downloads

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s. Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s

Preventive Maintenance Downloads

Download your free Preventive Maintenance Schedule, Preventive Maintenance Log, and Incidental Maintenance Log.

Preventive Maintenance & Repairs Resource Download

Questions about costs, timelines and requirements?

Contact Us Today for a Free Consultation

Available to travel for your project

-

Headquarters

-

Offices