Episode 4: Short Term Planning for Validation and Verification

Episode 4: Short Term Planning for Validation and Verification

In this video we will focus on short term validation in the facility, which we want to perform annually. Validation within this time frame generally addresses the requirements found in safety and quality programs for demonstrating that plans, pre-requisite programs, GMPs, and critical equipment is capable of functioning as intended, and that monitoring records are in place to demonstrate the plan was effectively followed each day of operations.

Here, we are including the requirement to evaluate the results of pre-existing safety and quality plans, even when the original validation was performed prior to the annual time frame. As we look at short term validation and verification, we will be explaining how to prepare a complete validation study for equipment in operation.

Short-term Validation Assessment Benefits

Where the sources of long-term validation in a facility may be difficult to assess and harder to change where invalidation is evident, short term validation assessments allow for clearly defined time periods, and when properly performed, focus on defined measurement and metrics to define what is correct.

When thinking about short term aspects of our program that should be validated, we should consider each program within operations, not just a food safety plan or a piece of equipment. That means operations and quality should be able to clearly define what needs to occur for each part of operations to be functioning correctly. This statement does not need to be long or complex, but it should be written down and reviewed each year, as it is possible, and even likely that each program will change during a year so the original validation statement may no longer be accurate.

As part of short-term validation assessments we also need to have defined records demonstrating verification, and those records should be controlled records that have titles or identifiers. The documents need to be readily available for review by a qualified individual within the organization, as well as third party regulators and auditors.

Validation Assessment Format

The format a facility chooses to use to record a validation statement is not defined by regulatory bodies or certification schemes, which leaves each organization to document validation in their preferred method.

Kellerman Consulting prefers the use of either validation forms created with prompts to guide the user through creating a validation statement, or a log that covers programs in a collected document, but again, all formats are acceptable as long as they are approved by the organization, completed in an understandable way and reviewed at least each year.

Free Validation & Verification Assessment Log Download

Hygiene, Sanitation & Maintenance Validation

Starting with the sanitation program, validation needs to focus on the use of valid chemical agents and/or techniques for removing unsanitary conditions, which should include biological and chemical hazards as defined by a hazard analysis or failure mode. Valid chemicals are procured from authorized sources, and what that source is must be included. Techniques or equipment must have manuals or instructions for effective use, and like chemicals, must come from an authorized source.

With valid chemicals or techniques, there must also be proper instructions. These are validated through observing the cleaning being performed and confirming that the people involved, the instructions for cleaning each piece of equipment, as well as the frequency of cleaning, are capable of completing the cleaning task correctly and effectively.

Maintenance is validated in a similar method as sanitation, and is achieved through the presence of appropriate tools and equipment adequate enough to perform maintenance for operations.

That means for complex production equipment, the recommended tools, calibration and diagnostic equipment are on hand for maintenance, and there is adequate space and an adequate number of employees to perform maintenance according to a schedule, to make repairs as instructed and to organize and maintain their work areas.

Valid Hygiene

Moving on to hygiene, validation is that hygiene requirements are robust enough to assure workers and visitors are able to start their work clean, and maintain cleanliness while on site.

To achieve validation associated with hygiene, work clothing requirements must meet the risk levels for operations and there must be enough replacement uniforms, smocks or aprons on hand for incidents.

Also required for valid hygiene is enough handwashing stations and bathrooms for the number of employees, and that employees have been trained to understand hygiene requirements, clothing requirements and proper hand washing sources

The verification of these steps takes place during GMP walk through inspections, and where non-conformances and errors are noted, it may be treated as signs of invalid hygiene.

Master Verification Action

It’s important to remember that internal auditing, which we covered in a previous video series, is the master verification action.

Internal auditing is the review of verification records for the sanitation program, maintenance program, pest control, hygiene, shipping receiving and the other pre-requisite programs that are in place in your facility.

When the internal auditing program is performed correctly, we should be able to identify both the requirements for valid programs, as well as the records that prove validation of those programs.

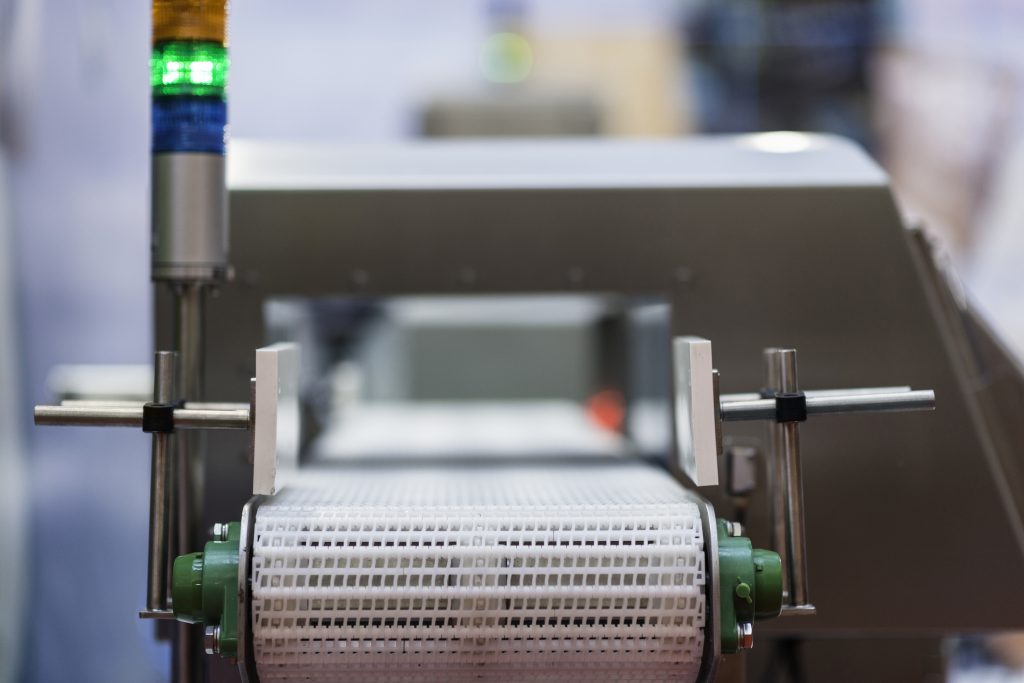

In our next video, we will be focusing on validation and verification of critical safety and quality equipment in operations, as well as the regulatory requirements for validating and verifying equipment.

If you would like to discuss having Kellerman Consulting write and implement your food safety and quality management system program, contact us for a free consultation.

Validation & Verification Resources