For facilities with established environmental monitoring programs, drains present a unique challenge and opportunity to monitor for organisms, and thinking through the approach to including or excluding drains from the swabbing schedule is important.

As we take a look at drains in food and food packaging facilities, we want to mainly focus on operational drains, so those drains that are in GMP areas if they are present in the facility.

For operations with drains, and that should be most food and food packaging facilities, employees should have an up-to-date understanding of how many drains are present in operations, and where they are located. Remember, drains in bathrooms, offices and break rooms are important to monitor generally, but they are not usually a part of an environmental monitoring program unless we have already identified that those non-GMP areas are a source of environmental contamination, so stick with production drains for now.

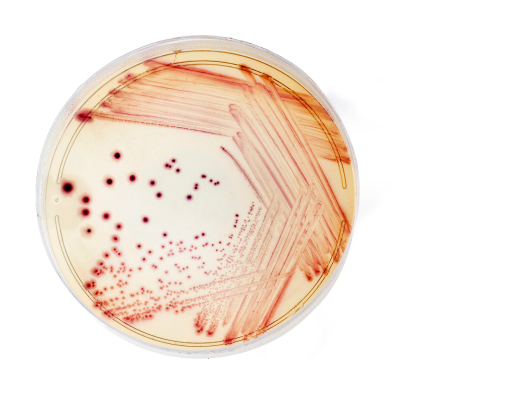

Drains are important because they receive all of the water and waste from the immediate area around them, and tell us what is going on in that room.

If we have molds, yeast and environmental pathogens in a production area, the runoff into the drains are likely to carry those organisms into drains, where we can then find them.

For facilities that choose to target drains as part of the environmental monitoring program, doing so should be performed with the full risk of finding pathogens within the drains . As I mentioned at the beginning of this series, if we swab for pathogens, we want to find them, not effectively remove them in an non-representative way just to get the results we want. This gives us a false sense of security, limits our ability to make appropriate decisions in the facility, and may put operations at risk for very short term benefits.

In our next episode, we are going to look at swabbing patterns and swabbing approaches in scheduling and location selection to get the best representative results, and to make sure we do not have a stagnant approach that prevents us from seeing the bigger picture of bacterial risks in the facility.

Thank you for watching. For free downloads to accompany this video series, visit the free training videos & resources page of our website.

Subscribe to our YouTube channel or follow us on LinkedIn to be notified of new educational food safety resources.