Food Safety Compliance

We stay with you until you pass. No matter what.

100%

Pass Rate

700+

Happy Clients

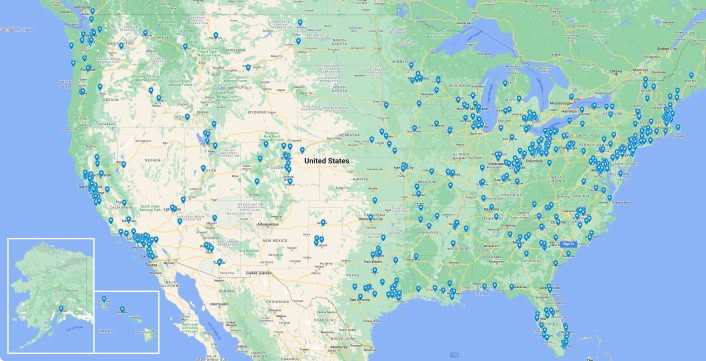

50

States

FDA & USDA Compliance to Pass Your Next Inspection

We’ve assisted 700+ companies like yours to become compliant with the U.S. Food and Drug Administration (FDA) and the U.S. Department of Agriculture (USDA) regulations by writing your food safety compliance program, training you to implement it, and staying with you until you pass your inspection.

Get Results-Driven FDA & USDA Consulting with a family-run team who knows food safety cover to cover.

What to Expect During Your Free FDA & USDA FSIS Consultation

During your free FDA / USDA consultation, you’ll learn what the requirements are for getting in compliance, how much it costs with no hidden fees, how long it takes, and how our process works to assure you pass your upcoming inspection.

Common Food Safety Regulatory Compliance Questions

What is the Difference Between Food Safety Compliance vs. Food Safety Certification?

Food safety law is designed to protect the safety of consumers. Food businesses must do their part by following food law in order to meet food safety compliance standards and ensure the safety of their products . Food safety compliance is mandatory, whereas, food safety certification is a voluntary process that many food industry businesses choose to pursue to improve the performance of their company, to stay competitive, to sell to larger customers and to uphold high safety and quality standards of their products.

What are Key Elements of Food Safety Compliance?

Key elements of food safety compliance include: Hazard Analysis, Risk Assessments, Preventive Controls, Critical Control Points (CCPs), Defined critical limits, Monitoring procedures, Corrective Actions, Identified Verification Procedures, setting up documentation and record-keeping processes. Kellerman Consulting will write your food safety compliance programs and we will train you to implement it to pass your next inspection.

What is FDA Food Safety Compliance?

In the United States, the Food and Drug Administration (FDA) regulates: “human drugs and biological products, animal drugs, medical devices, tobacco products, food (including animal food), cosmetics, and electronic products that emit radiation”. The FDA regulates food items in the U.S., except for meat and poultry products, which are regulated by the U.S. Department of Agriculture (USDA). The FDA conducts periodic inspections and food facilities should be prepared for an inspection at any time. There are also compliance regulations related to importing food products into the U.S. called the Foreign Supplier Verification Program (FSVP). Kellerman Consulting has written over 650+ FDA / USDA food safety programs that comply with government standards and we stay with our clients until you pass. No matter what.

What is USDA Compliance?

USDA compliance is enforced by the Food Safety and Inspection Service (FSIS). FSIS is an agency of the USDA and it is responsible for ensuring the safety of the United States supply of meat and poultry products. FSIS conducts continuous inspections of meat and poultry processing.

Learn From Our Clients’ Experiences

Questions about costs, timelines and requirements?

Contact Us Today for a Free Consultation

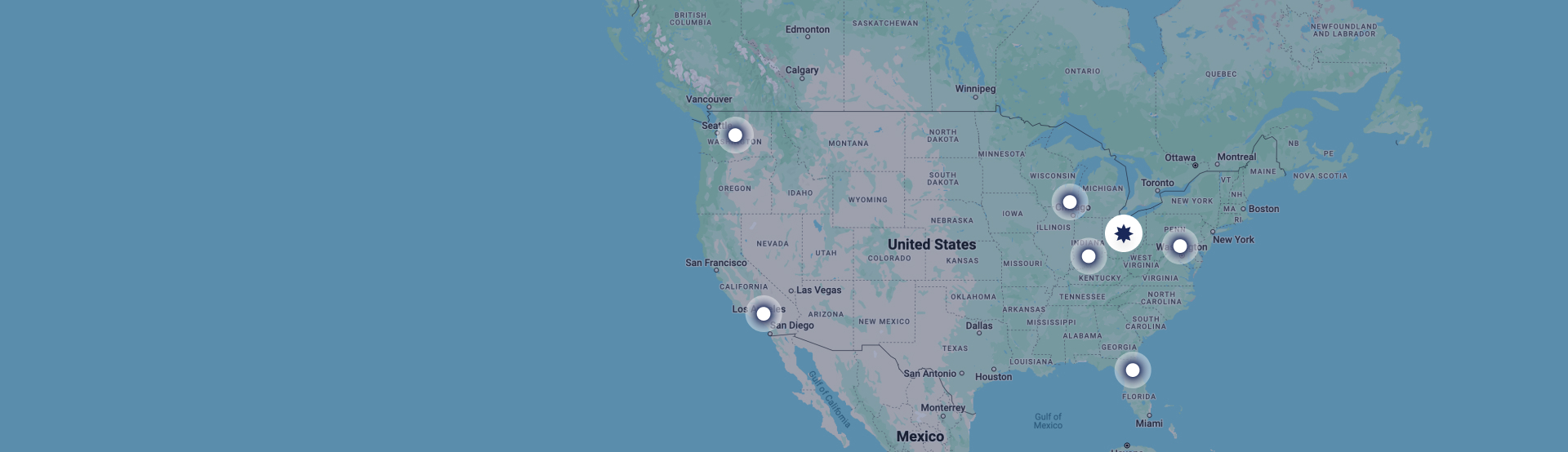

Available to travel for your project

-

Headquarters

-

Offices